Introduction

This tutorial will guide you through the process of cryo-fixation of adherent cells grown on 6 mm sapphire disks at the Center for Microscopy and Image Analysis, UZH, Zurich.

-

-

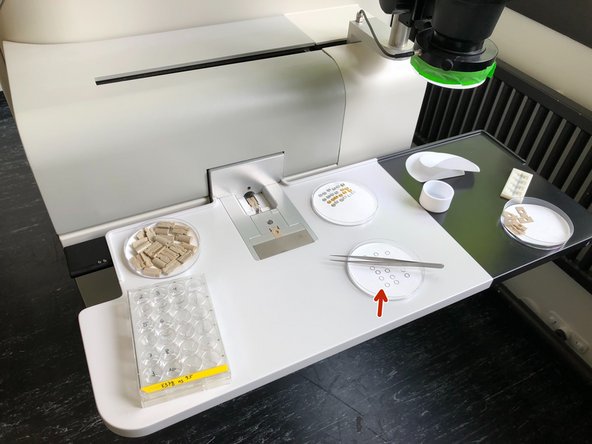

Prepare your tools and parts for high-pressure freezing. In the cupboard above the machine you will find:

-

the three-piece cartridge consiting of an upper cylinder, special middle plate 6 mm and lower cylinder

-

spacer rings 6 mm (200 μm)

-

carriers 0.1/0.2 mm

-

filter paper

-

mini-rack for middle plates

-

metal block

-

petri dishes

-

-

-

In the cupboard on the main floor you will find:

-

2x HPF-tweezers

-

1x orange tweezer

-

LN2 sample storage box

-

box with 1-hexadecene Eppendorf tubes

-

screwdriver for LN2 sample storage box

-

EtOH glas beaker

-

heating plate

-

-

-

Prepare all tools and accesories required for your cryofixation experiment.

-

Check if the 200 µm spacer rings are completely flat otherwise replace them.

-

-

-

Organize the required 100/200 cavities on a filter paper in a petri dish.

-

For 6 mm sapphire disks the 100 µm cavity must face the cells on the sapphire disk.

-

-

-

Insert the two-piece cartridge consisting of an upper cylinder and lower cylinder in the loading mechanism.

-

-

-

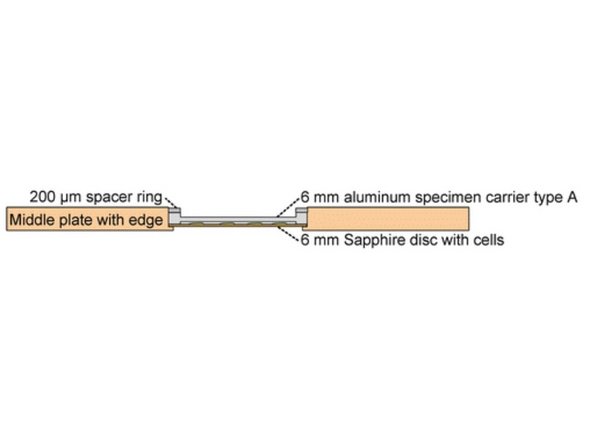

Overview of sandwich configuration

-

-

-

Visualization of sandwich configuration

-

-

-

Hold the sapphire at 45°.

-

Align the edge within the recess of the middle plate.

-

Release it.

-

-

-

Take a aluminium specimen type A (100/200 µm cavity) carrier with 100 µm cavity down and only wet this side with 1-hexadecane.

-

-

-

Add the 200 µm spacer ring on top.

-

Move the middle plate to the loading station.

-

-

-

Blot excess liquid away using filter paper.

-

Important here is that you blot fast and put some pressure to prevent shifting of the 200 µm spacer ring.

-

Flip the loading lever 180° until the process button is in position.

-

Initiate freezing by pressing the button.

-

-

-

After cryofixation, the two-piece cartridge and the specimen carriers are automatically ejected into the specimen dewar and are ready for transfer.

-

Open the sample dewar drawer and transfer the sample dewar to LN2 box.

-

-

-

Always pre-cool the tweezers prior to use.

-

Transfer all components including your sample to the LN2 box.

-

-

-

Always pre-cool the tweezers prior to use.

-

First, transfer the sapphire disk to the LN2 sample storage box.

-

Then transfer the specimen carriers to a beaker filled with 70% EtOH for cleaning.

-

-

-

Place the sample dewar back into the high-pressure freezer drawer.

-

-

-

Place specimen carriers to a hot plate for drying.

-

-

-

Once all freezing is complete the two valves at the back can be opened. Allow LN2 to drain.

-

-

-

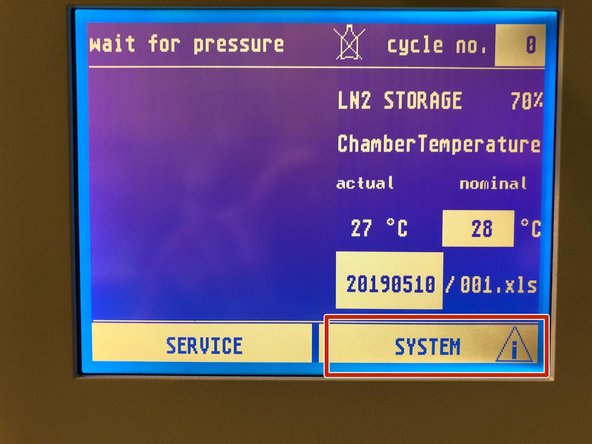

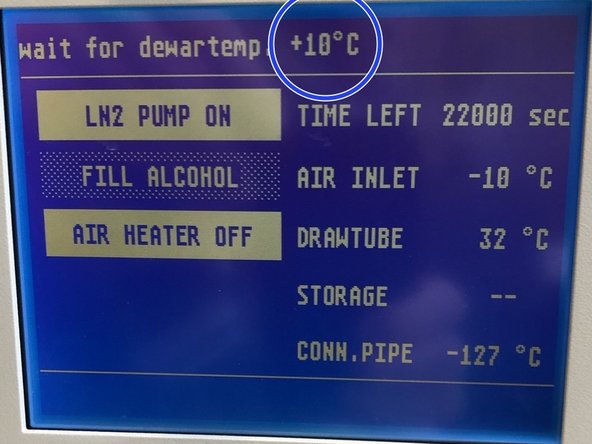

Once the storage dewar has reached a level of below 20% select SYSTEM form the main screen.

-

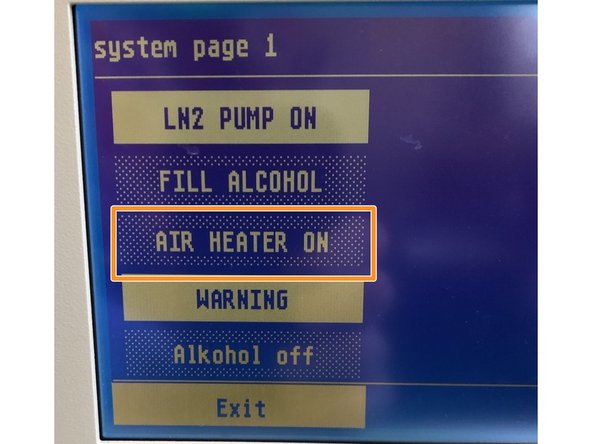

Select AIR HEATER ON.

-

This activates the heating cycle. The 80°C heating cycle will only start once the chamber temperature warms up to 10°C.

-

The bake out will automatically terminate at the end of the cycle leaving the instrument ready for the next user.

-

NOTE: Leave the main power to allow the heating cycle to run.

-

Once the air heating cycle is started, the compressor turns on "air heater working".

-

Once the cycle is complete the machine switches back to the standard screen and you can turn it off using the switch at the front.

-